Styrofoam Plant

The longest time I spent in an operating unit at Dow, I spent in the Styrofoam Plant, where I was for the final 5 years of my Dow life.

Getting the Job

I took the job. I think it was the fact that it was a new plant, with good potential for remaining, whereas EO was old and possibly too small a producer for the markets that were opening up. I figured that since Herbicides was closing down, EO could be next. Also, new plant meant new knowledge and at this point I was really interested in learning. (In high school, I was so bored, that I would skip classes in the afternoon so I could go home and watch People’s Court with Judge Wapner...).s

Monday, October 26, 2020

I remember when the call came out for operators for the plant and in particular, the notice for 2 Supervising Technicians. Two SuperTechs, Big Bob and Reg had already been moved into that area from Herbicides Plant. They were allowed some say in who was hired for the other 2 spots. One of them went to Randy, formerly from the Chlor-Alkali Plant. When I didn’t apply for the job, I got a phone call telling me that I was selected, and would I please apply if I wanted the job. Basically the job was mine. I was apprehensive because I had just completed my SuperTech relief at EO, pretty well guaranteeing me the job of SuperTech if one came up. The complex was growing, people were moving around, so I knew I wouldn’t have to wait too long.piI took the job. I think it was the fact that it was a new plant, with good potential for remaining, whereas EO was old and possibly too small a producer for the markets that were opening up. I figured that since Herbicides was closing down, EO could be next. Also, new plant meant new knowledge and at this point I was really interested in learning. (In high school, I was so bored, that I would skip classes in the afternoon so I could go home and watch People’s Court with Judge Wapner...).s

Send Comments

Portable Plant

Since none of the trailers had been delivered yet, all the operators and Supervising Technicians sat in some temporary offices that served as a classroom and took training offered by a couple of guys from our Weston, Ontario, Styro Plant. Getting training this way was not too effective: it was like teaching someone how to drive a car, when they’ve never seen a car in their life. But we lived through it.

Monday, October 26, 2020

The first Styro plant was a portable unit, a complete Styrofoam Plant built on trailers capable of being pulled around from place-to-place by tractor units. The idea was to see if a Styrofoam plant was feasible: something that could be moved around to where the markets were, instead of making the product here and shipping it half way across the world. Then, if a market proved fruitful, a full- scale static plant would be built.Since none of the trailers had been delivered yet, all the operators and Supervising Technicians sat in some temporary offices that served as a classroom and took training offered by a couple of guys from our Weston, Ontario, Styro Plant. Getting training this way was not too effective: it was like teaching someone how to drive a car, when they’ve never seen a car in their life. But we lived through it.

Trailers

We ran this plant for a year, made new markets where there were none before, then started building a new static plant. The portable plant was dismantled to the "trailer-level", (still keeping most of our enhancements) and sent to Abbu Dhabi in Saudi Arabia.

As the startup date for the static plant crept closer and closer (we HAD to start up before the end of the year, for tax purposes) we had about 10 people on each of two 12 hour shifts working without days off for about 1-1/2 months. If someone wanted a day off he could take it, but if he wanted to work, as I did, he worked straight through. Dow paid us overtime for anything past 40 hours in a week, so we essentially were all being paid time and half or double time. I made a whole bunch of money. They also supplied us with catered meals on shift, and breaks when we wanted them. We worked our butts off, but we did it for an appreciative employer who recognized our efforts. After a successful startup, the company took us all out for a dinner at one of the best restaurants in Edmonton.

I used to venture over to the new plant (under construction while we were running the portable plant) every time I was on shift, to see what was going on. I remember huge holes, 3 feet in diameter and 60 feet deep being drilled for piles for the cement floor to be poured. When it rained heavily for one week, these holes, and there were lots of them, were full to the brim with water. It was kind of scary stepping on wet plywood sheets placed around these holes as a temporary floor.

The installers of the metal cladding on the building had slippery fingers, because all around the perimeter of the walls I found hundreds of plastic-coated self-tapping screws. Of course I picked them up and took them home. Even now, 20 years later, I reminisce every time I see the glass jar in my garage with these screws inside.

Tuesday, October 27, 2020

The trailers didn’t all come in one bunch, in fact I think it was the recycle trailer that came first. It was a trailer with a vertical extruder on it and equipment to cool a hot string of plastic then chop it up into little pieces. It also had a large storage bin that held chopped up Styrofoam. When this trailer arrived, it was obvious that it needed work. The trailer had all the equipment on it, but there were electrical connections to be made, water for the water bath, a drain for the water bath, guard rails and such. We had something like 7 trailers total and they came in every other week. I think they were still building the things back in Michigan while we were modifying them for our own needs.We ran this plant for a year, made new markets where there were none before, then started building a new static plant. The portable plant was dismantled to the "trailer-level", (still keeping most of our enhancements) and sent to Abbu Dhabi in Saudi Arabia.

As the startup date for the static plant crept closer and closer (we HAD to start up before the end of the year, for tax purposes) we had about 10 people on each of two 12 hour shifts working without days off for about 1-1/2 months. If someone wanted a day off he could take it, but if he wanted to work, as I did, he worked straight through. Dow paid us overtime for anything past 40 hours in a week, so we essentially were all being paid time and half or double time. I made a whole bunch of money. They also supplied us with catered meals on shift, and breaks when we wanted them. We worked our butts off, but we did it for an appreciative employer who recognized our efforts. After a successful startup, the company took us all out for a dinner at one of the best restaurants in Edmonton.

I used to venture over to the new plant (under construction while we were running the portable plant) every time I was on shift, to see what was going on. I remember huge holes, 3 feet in diameter and 60 feet deep being drilled for piles for the cement floor to be poured. When it rained heavily for one week, these holes, and there were lots of them, were full to the brim with water. It was kind of scary stepping on wet plywood sheets placed around these holes as a temporary floor.

The installers of the metal cladding on the building had slippery fingers, because all around the perimeter of the walls I found hundreds of plastic-coated self-tapping screws. Of course I picked them up and took them home. Even now, 20 years later, I reminisce every time I see the glass jar in my garage with these screws inside.

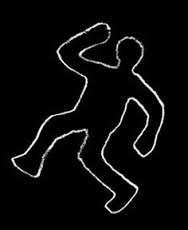

Fatality

Tuesday, October 27, 2020

The warehouses were built first so that we could continue production with the old plant and have storage space readily available. A fatality occurred in one of these warehouses during construction. A metal worker was working on a girder for the roof of the building which was about 35 feet from the concrete floor. He was wearing a safety line as dictated by the rules, but as he moved, he had to move his line. He reached over and disconnected it on one side of a perpendicular support, then reached again to get the hook on the other side of the same support. In so doing, he over-stretched and fell to his death. This happened on the day shift. I worked night shift that night and got all the details from a very upset SuperTech who had been the first to respond to the incident. When I went to investigate the area, there was a large red stain on the concrete. The man who died was only in his 20’s.

New Plant

Tuesday, October 27, 2020

When the new plant was built, the old plant area was turned into a training center. When I see pictures of the old plant next to the new plant with it’s big warehouses, the area where the portable unit was looks so tiny! It was no wonder then why we had to store the foam outside. We just didn’t have the warehouse space in the portable plant. Styrofoam, like most plastics, deteriorates under sunlight (try telling that to the environmental bleeding hearts), turning from a light blue to a pastel yellow. The colour change also indicates structural change: the yellow parts crumble into dust like termite-infested wood. We had the Styrofoam covered with plastic, for protection from rain but it didn’t offer protection from the sun. Styrofoam is water-proof so I wasn’t sure why it was covered in the first place. The trailers were not anchored to the floor; in fact the wheels were left on to help support the back end of the trailer, with big jacks handling the bulk of the weight. The wiring and the piping had to be flexible so that vibration of the equipment wouldn’t dislodge or break the connections. One night I was sitting at the desk on the production floor near the extruder trailer when a 4 inch rubber hose connecting cooling water to the trailer broke off. At 85 psig, there was more flow than the sewers could handle and the floors rapidly became flooded. When I saw the first wave coming at me from under the trailer, I ran around to see what the problem was, then shut the plant down quickly. Without cooling water we could not produce Styrofoam.

The Mole People

The most obvious solution to connect them was to cut a channel from A to B and put a trough or piece of pipe between them. Well, "they" didn’t want to wreck the cement floor so they came up with a plan to send a "bullet" from one hole to another, creating a channel for the pipe to follow. This bullet looked like a torpedo, was about 3" in diameter and 3 feet long and was driven by compressed air. First they had to dig a hole big enough so they could place the torpedo level within it. Since the desk sat where the hole would be dug, this was deemed appropriate sacrifice of the concrete at this spot. So they jack-hammered a 3 foot square hole, not a very nice one, and dug down in the sand and clay about 2 feet. They were ready for the mole.

First try, the bullet went far enough but it took a left turn and missed the target by 6 feet. They had much difficulty pulling the bullet back, because it was pointy at the front, not the back. This was not the normal direction of flow. How easy does a boat travel backwards?

Second try, the bullet went far enough but it took a right turn and missed the target by 6 feet. Once again it was difficult to retrieve the bullet. One attempt per day is all they could do.

Third try, they were too short, but retrieved the bullet. The problem this time was too little air pressure, which they increased for the next try.

Fourth try, they went too far by 20 feet.

Fifth try, they went short again but were right on target. This time they could not retrieve the bullet, no matter what they did. So....they had to jack-hammer a 3 foot hole in the middle of the floor, 10 feet away from both drains, to rescue the torpedo.

I was off shift for 3 days. When I returned there were 3 patches where 3 holes were dug, and a long narrow patch 6 inches wide that connected all of them together. They had given up with the torpedo idea and just dug the channel out of the cement. It took them about 8 days to do a job that a concrete cutting machine could have done (nicely) in about an hour. Heh heh heh.

Tuesday, October 27, 2020

Because we were almost flooded out in this situation, it was obvious we needed more drainage. There was a drain by the extruder trailer, the one mentioned in the previous paragraph. This one was in the middle of a long sump, basically just a trough cut out in the cement, with a metal grating on top. There was another drain, just a floor drain, about 20 feet away from the trailer. These two drains were not connected together and someone came up with the idea to connect them, thereby giving us more draining capacity.The most obvious solution to connect them was to cut a channel from A to B and put a trough or piece of pipe between them. Well, "they" didn’t want to wreck the cement floor so they came up with a plan to send a "bullet" from one hole to another, creating a channel for the pipe to follow. This bullet looked like a torpedo, was about 3" in diameter and 3 feet long and was driven by compressed air. First they had to dig a hole big enough so they could place the torpedo level within it. Since the desk sat where the hole would be dug, this was deemed appropriate sacrifice of the concrete at this spot. So they jack-hammered a 3 foot square hole, not a very nice one, and dug down in the sand and clay about 2 feet. They were ready for the mole.

First try, the bullet went far enough but it took a left turn and missed the target by 6 feet. They had much difficulty pulling the bullet back, because it was pointy at the front, not the back. This was not the normal direction of flow. How easy does a boat travel backwards?

Second try, the bullet went far enough but it took a right turn and missed the target by 6 feet. Once again it was difficult to retrieve the bullet. One attempt per day is all they could do.

Third try, they were too short, but retrieved the bullet. The problem this time was too little air pressure, which they increased for the next try.

Fourth try, they went too far by 20 feet.

Fifth try, they went short again but were right on target. This time they could not retrieve the bullet, no matter what they did. So....they had to jack-hammer a 3 foot hole in the middle of the floor, 10 feet away from both drains, to rescue the torpedo.

I was off shift for 3 days. When I returned there were 3 patches where 3 holes were dug, and a long narrow patch 6 inches wide that connected all of them together. They had given up with the torpedo idea and just dug the channel out of the cement. It took them about 8 days to do a job that a concrete cutting machine could have done (nicely) in about an hour. Heh heh heh.

Learning from Old Plant

Tuesday, October 27, 2020

We learned quite a bit from running the old plant, like safety considerations, operating procedures, what equipment worked and what didn’t. For example for two streams of blowing agent (gases that "puffed up" the styrene into Styrofoam) we had electric control valves instead of the traditional pneumatic valves common in the process industry. These valves had large stepper motors with linear actuators on them that moved up and down, opening or closing the valve. These never worked properly, especially when they were closed. In this position, they would sit in that one spot and slowly shake or vibrate because the motor was still getting a small signal to keep the valve closed. This wore out the valve plug and seats quite rapidly, so that when the valve was supposedly closed it would pass gas into the mixer where the hot styrene was. When the plant was started up, this gas came out in one big blast, blowing up the board, destroying the Teflons, creating havoc. Then too, with worn valve parts we never really knew how much blowing agent we were really adding. When Dow started design of the new plant we insisted that these valves be pneumatic so that the continuous "hunting" for a position wouldn’t happen. With a pneumatic valve, when the valve was closed, the valve WAS closed.

How it is Made

Styrofoam is basically puffed up styrene and styrene is just a type of plastic. It is somewhat distinct from "bead-board" which many people call Styrofoam. Those white peanuts used for packing? That’s bead board. Coffee cups? Beadboard. Insulation for houses and commercial buildings (roofs and walls), and blue? That’s Styrofoam. (When I was making Styrofoam, it was always blue, but I have seen Styrofoam with the Dow trademark on it, that was PINK!)

Bead-board or that white pseudo-styro-stuff is made by blasting beads of styrene with hot steam or air, puffing them up like a popcorn popper does to popcorn, or puffing up rice to make rice cakes. The hot molten plastic is then put into forms like cups, flat board, or packing for your new computer equipment. The stuff you buy in a can and spray into crevices or to make your own packing is a chemical process and is actually urethane foam.

Styrofoam uses two chemicals, called blowing agents, that are mixed in with hot styrene. When the foam comes out of the die, the sudden depressurization causes the gasses to come out of the solid "gel" and in so doing, "foam" the material. Some of the gases stay in the Styrofoam, supposedly for up to 25 years, and this is what gives Styrofoam its strength.

Both types of foam have a cellular structure. Bead board is considered an "open cell" and Styrofoam is "closed cell". The closed cell holds in the gases and under a microscope looks similar to a honeybee’s honeycomb.

Tuesday, October 27, 2020

This is how Styrofoam is made. The techniques are quite well known, but the actual operating parameters are not, so to protect Dow’s patents I won’t divulge any trade secrets. I can’t remember all the exact details anyway.Styrofoam is basically puffed up styrene and styrene is just a type of plastic. It is somewhat distinct from "bead-board" which many people call Styrofoam. Those white peanuts used for packing? That’s bead board. Coffee cups? Beadboard. Insulation for houses and commercial buildings (roofs and walls), and blue? That’s Styrofoam. (When I was making Styrofoam, it was always blue, but I have seen Styrofoam with the Dow trademark on it, that was PINK!)

Bead-board or that white pseudo-styro-stuff is made by blasting beads of styrene with hot steam or air, puffing them up like a popcorn popper does to popcorn, or puffing up rice to make rice cakes. The hot molten plastic is then put into forms like cups, flat board, or packing for your new computer equipment. The stuff you buy in a can and spray into crevices or to make your own packing is a chemical process and is actually urethane foam.

Styrofoam uses two chemicals, called blowing agents, that are mixed in with hot styrene. When the foam comes out of the die, the sudden depressurization causes the gasses to come out of the solid "gel" and in so doing, "foam" the material. Some of the gases stay in the Styrofoam, supposedly for up to 25 years, and this is what gives Styrofoam its strength.

Both types of foam have a cellular structure. Bead board is considered an "open cell" and Styrofoam is "closed cell". The closed cell holds in the gases and under a microscope looks similar to a honeybee’s honeycomb.

Feed the Stock

to fall out.

Similarly, we had a reclaim silo that held previously melted and pelletized Styrofoam that used the same method. Reclaim was about 30% of the total feed stock, styrene about 60% and 10% was additives. The styrene was little clear pellets, while the reclaim, which was concentrated, melted, Styrofoam was a dark blue color..

Moving the reclaim into the plant to the feeders was done with a slightly different method than using cyclones. A "star" valve was a 4 vane gate that turned slowly, admitting a certain amount of material on each turn. This was like those candy vending machines where you turn a crank to open up a port just enough to let a measured amount of candy drop out. In our case though, this was not necessary for measurement, just solids dispensing. A blast of air would push the material out of the star gate and into the feed hoppers on the second floor of the building. This was a continuous process. At times we could be off-loading styrene, and moving the silo contents into the plant hoppers at the same time.

Tuesday, October 27, 2020

Styrene beads were imported from the Dow plant in Sarnia, Ontario, and shipped to us in hopper cars. We off-loaded the material using a suction wand connected to a device called a cyclone. This cyclone was a large hopper that had a continuous diameter on top, but an increasingly smaller diameter on the bottom; in other words, cylindrical on top, conical on the bottom. When air containing solids in suspension entered into the top of this thing, the beads would swirl around the inside until they slowed sufficiently to drop out at the bottom. The air, being lighter would exit through the top. So the styrene would be transported right up to the top of the tall styrene storage silo by this method. Really it was a big vacuum cleaner with a hole in the bag for the dust to fall out.

Similarly, we had a reclaim silo that held previously melted and pelletized Styrofoam that used the same method. Reclaim was about 30% of the total feed stock, styrene about 60% and 10% was additives. The styrene was little clear pellets, while the reclaim, which was concentrated, melted, Styrofoam was a dark blue color..

Moving the reclaim into the plant to the feeders was done with a slightly different method than using cyclones. A "star" valve was a 4 vane gate that turned slowly, admitting a certain amount of material on each turn. This was like those candy vending machines where you turn a crank to open up a port just enough to let a measured amount of candy drop out. In our case though, this was not necessary for measurement, just solids dispensing. A blast of air would push the material out of the star gate and into the feed hoppers on the second floor of the building. This was a continuous process. At times we could be off-loading styrene, and moving the silo contents into the plant hoppers at the same time.

Feeding the Masses

Tuesday, October 27, 2020

All feed-stock had a hopper that dropped material onto the drive belt of a "mass-feeder". These high tech devices had a scale under the rotating belt so that it weighed the material and adjusted the speed of the belt accordingly. Full feedback control. If a big clump of matter fell on the belt, the belt would slow down, and conversely, if the hopper outlet became plugged, the feed belt would jump to top speed, to try and match our setpoint for feed required.

Vibrators, Ooohh I'm Tingling Already

Thursday, October 29, 2020

The powdery additives had electric vibrators mounted to the side of the hopper to keep the material from bunching up inside the vessel, instead of flowing freely. Styrene and reclaim which were hard plastic granules flowed quite well unless there was moisture present. The styrene hopper cars all had vibrators mounted on their outlets for just this reason: moisture in the car made the styrene particles stick to each other. Many times, for all feeds, for cars or in-plant hoppers, we would have to beat the hell out of the cars or in-plant hoppers with a sledge hammer to get the feed going again. The vibrators sometimes had the opposite effect: making the powders more dense in the bottom of the hopper. I have since read about a scientific study done about this effect and indeed, vibration packs down solids rather than "loosening" them up.

Fire Retardant

One day management was evaluating vacuum cleaners and floor sweepers and they asked me to go through the trials since I was the SuperTech on shift. The salesman had brought a couple different types and was extolling their virtues when I decided to challenge him. Or his machines. Sure, the machines picked up the usual dirt and dust, and did a good job of reclaim chunks on the floor, but how would it work on FR-651? I poured some on the floor and ran the sweeper over it. Failure! Failure! The machine didn’t pick up on the first pass or the second pass, much to the chagrin and embarrassment of the salesman. My supervisors were happy that I put the machine through it’s paces and found a failure. We eventually got a sweeper that was self-propelled and had a fine enough brush that it would pick up the retarded dust. Self-propelled meant one just had to walk behind it because it had motive power to the wheels. Sometimes a person could sit on the unit and hit the control to get a free ride and sweep the floor at the same time. More than once I sat in my wheeled swivel-chair behind the sweeper and let the machine pull me around.

Another additive was indigo. This was the coloring agent that made the Styrofoam blue, and was itself, purple-colored. This is the same material that is used to make blue-jeans blue. Indigo also affected the cell size of the foam so we had to take into account it’s effect when we added it to the mix, because cell size affected density and R-value. Reclaim already had indigo in it, so if we upped the reclaim, we decreased the indigo. Then, to keep the cell size correct, we modified the flow of another additive that was there just to control cell size.

This dusty concoction was dumped into a small hopper that fed a tube connected to the inlet of the extruder. The extruder was a massive machine and was the heart of the entire process. Basically a big, heavy duty, screw auger, it compressed the chemicals, melting them together in the process. To control the production rate, we varied the speed of the 500 HP DC motor that drove the extruder screw, which in turn varied the feed-rates of the feeders. The extruder barrel was heated with electric heaters so that we could heat the unit up before a startup and melt any material still in the barrel. The outlet of the extruder was double-wall pipe heated with hot oil. This was special pipe that required careful welding, because the oil was at 230 degrees C, and the pressure at the extruder outlet was over 2000 psig.

Thursday, October 29, 2020

One of the additives we mixed in with the styrene and reclaim was a product called FR-651 which was a fire-retardant made by Dow at another plant in the USA. This made the Styrofoam fire-retardant, not fire-proof, but when I put an acetylene torch to a piece, it never caught fire, so I would call it fire-proof. The latter term I think is in reference to an item not being destroyed in a fire, which of course Styrofoam did, by melting. Fire-retardant meant it did not support combustion. This FR-651 was terrible stuff to work with, causing all kinds of skin rashes, was terrible to breathe in, made one’s eyes water. This is when we were wearing the proper safety equipment! It was a very fine dust, smaller particles than flour, and was slippery such that one could actually slip on this material when it was on the floor. It was very difficult to sweep up because of it’s cohesive properties. You would be correct in saying that this material would be one of the most difficult to handle in the hoppers and feeders. One day management was evaluating vacuum cleaners and floor sweepers and they asked me to go through the trials since I was the SuperTech on shift. The salesman had brought a couple different types and was extolling their virtues when I decided to challenge him. Or his machines. Sure, the machines picked up the usual dirt and dust, and did a good job of reclaim chunks on the floor, but how would it work on FR-651? I poured some on the floor and ran the sweeper over it. Failure! Failure! The machine didn’t pick up on the first pass or the second pass, much to the chagrin and embarrassment of the salesman. My supervisors were happy that I put the machine through it’s paces and found a failure. We eventually got a sweeper that was self-propelled and had a fine enough brush that it would pick up the retarded dust. Self-propelled meant one just had to walk behind it because it had motive power to the wheels. Sometimes a person could sit on the unit and hit the control to get a free ride and sweep the floor at the same time. More than once I sat in my wheeled swivel-chair behind the sweeper and let the machine pull me around.

Another additive was indigo. This was the coloring agent that made the Styrofoam blue, and was itself, purple-colored. This is the same material that is used to make blue-jeans blue. Indigo also affected the cell size of the foam so we had to take into account it’s effect when we added it to the mix, because cell size affected density and R-value. Reclaim already had indigo in it, so if we upped the reclaim, we decreased the indigo. Then, to keep the cell size correct, we modified the flow of another additive that was there just to control cell size.

This dusty concoction was dumped into a small hopper that fed a tube connected to the inlet of the extruder. The extruder was a massive machine and was the heart of the entire process. Basically a big, heavy duty, screw auger, it compressed the chemicals, melting them together in the process. To control the production rate, we varied the speed of the 500 HP DC motor that drove the extruder screw, which in turn varied the feed-rates of the feeders. The extruder barrel was heated with electric heaters so that we could heat the unit up before a startup and melt any material still in the barrel. The outlet of the extruder was double-wall pipe heated with hot oil. This was special pipe that required careful welding, because the oil was at 230 degrees C, and the pressure at the extruder outlet was over 2000 psig.

Pipe Puzzle

Thursday, October 29, 2020

When the new plant was built, all the engineering and pipe fabricating was done off site and the parts were shipped to the plant site for us to put them together. The extruder and spline mixer were put in place, and two sections of the special double-walled pipe were attached on each machine. The pieces were supposed to meet in the middle where they would be attached to each other. They didn’t. In fact, they didn’t, they didn’t, they didn’t: the pipes were out of alignment in all 3 planes! Because of time constraints, it was decided to rebuild the pipe right there, using our own engineers and welders, rather than send the pipe back for re-work. Our guys did a formidable job because they built it right the first time, and that pipe stayed in there for the 5 years I ran the plant.

Hot OIl

Oil also circulated around the spline mixer which took the molten plastic, called gel, and mixed it with blowing agent, injected at high pressure of about 2500 psig. The mixer looked like a big section of 24" pipe, but at either end one could see pieces that were rotating in the center of the vessel. This was the splined mixer shaft. (The mixer was always called the spline mixer, never just "mixer"). To keep the hot gel from pushing out between the moving parts and the stationary parts, we employed special seals that were water-cooled. This froze the gel into hard plastic.

Thursday, October 29, 2020

Dealing with hot oil could have been a dangerous task, but there were enough controls and safeguards that it never became a problem. It was pretty well all self-enclosed and because of the necessary preparations made to keep it leak-proof, we never experienced leaks, spills, or accidents. Occasionally the oil temperature would be set too high, like around 235 deg C. and the oil would begin to smoke but that was as bad as it ever got.Oil also circulated around the spline mixer which took the molten plastic, called gel, and mixed it with blowing agent, injected at high pressure of about 2500 psig. The mixer looked like a big section of 24" pipe, but at either end one could see pieces that were rotating in the center of the vessel. This was the splined mixer shaft. (The mixer was always called the spline mixer, never just "mixer"). To keep the hot gel from pushing out between the moving parts and the stationary parts, we employed special seals that were water-cooled. This froze the gel into hard plastic.

Because I'm Blind, I Broke the Spline

The gel, with blowing agent mixed in with it was then sent to special plate coolers. This was the essence of Dow’s patents, these coolers, and the reason other competitors couldn’t duplicate our methods. We were told basically how they worked but were never shown any diagrams of how they were really built. (Although one night shift I snuck into the foreman’s office and found the plans.) They were special because they cooled the gel very evenly so that there were no hot-spots which would have created density zones in the board. The last "flat-plate cooler", the 3rd in the series was the most important. Here we had to control the gel temperature within 1 degree C or better just before it exited the die.

Thursday, October 29, 2020

One day in the old plant, I screwed up royally with these seals. After a plant shutdown when the spline mixer was not running, the cooling water to the seals would be shut-off so that the heat from the hot oil would heat the seal, allowing for startup of the mixer. If the seal was too cold and brittle, the mixer would not start because of the friction created by this solid plug. On this day, I had shutdown all the equipment, but since startup was now imminent, I turned the water off the seal. Since this was more or less standard operating procedure, I never mentioned it to the on-coming shift. Well, the SuperTech coming on shift didn’t start up until a couple of hours after I thought he would, and he started up thinking the water was still on the seal. When he put the full 2000 psig pressure on the end of the mixer, the gel came squirting out, making one hell of a mess. He turned the water onto the seal but it was to no avail: the seal just kept leaking. He had to shut the plant down so the millwrights could pull the seal out and replace it. This was a major job and took a couple man-days to complete. I was taken on the rug, but defended my actions as I have done here. However, my lack of communication still put me behind the eight ball. I screwed up.The gel, with blowing agent mixed in with it was then sent to special plate coolers. This was the essence of Dow’s patents, these coolers, and the reason other competitors couldn’t duplicate our methods. We were told basically how they worked but were never shown any diagrams of how they were really built. (Although one night shift I snuck into the foreman’s office and found the plans.) They were special because they cooled the gel very evenly so that there were no hot-spots which would have created density zones in the board. The last "flat-plate cooler", the 3rd in the series was the most important. Here we had to control the gel temperature within 1 degree C or better just before it exited the die.

A Board to Die For

The gel coming out of the die immediately foamed up, making a low frequency buzzing sound. Of the two blowing agent gases, one came out of the board immediately and was sucked away by a large overhead fan hooked up to a hood. This was the methyl chloride. The freon stayed in the board to form the cell structure. As the foam progressed out of the plates, it encountered another much larger, not adjustable flat plate, followed by a 6-foot long piece of metal conveyor rollers that prevented the foam from looping at that point. The rollers rolled on top of the foam, and in an emergency like a foam loop between the plates and this section, could be lifted in ½ second by tripping an air valve. This would allow us immediate access to the area to clear the mess. The SuperTechs had to measure the board numerous times in a shift right at that point, between the flat plate and the upper conveyor. A few times I got the measuring tape stuck and it went under the conveyor for it’s full length of 6 feet getting crushed into the hot foam. The emergency trip to lift the conveyor could have been used, but this could have caused a "loop" and it wasn’t worth the hassle. Now if that would have been my arm under there, that would have been a different story!

Thursday, October 29, 2020

The die was about 16" wide, for making 24" board. It could be smaller in width because of the expected expansion on exit. (I did that on purpose so I could have 3 words in a row with X in them..). The die was hard chrome and had to be perfectly flat, not only to create flat board, but also to keep the gel pressure up if we closed the die completely off. There was a top and bottom piece of the die, the top being the moveable section. On either side were the "shoes", big aluminum (for weight considerations) wedges covered with Teflon to guide the Styrofoam out of the gate. These were fixed and not adjustable, and could not be pulled out when there was material coming out of the die. There were also upper and lower plates that were adjustable. To open the die we had a large wheel, not as big as that on a ship, but similar in looks. Mounted somewhere on the moveable die was a dial indicator that read in thousandths of an inch. A typical die opening for making a 2-inch thick board was about 0.125" (an eighth of an inch).The gel coming out of the die immediately foamed up, making a low frequency buzzing sound. Of the two blowing agent gases, one came out of the board immediately and was sucked away by a large overhead fan hooked up to a hood. This was the methyl chloride. The freon stayed in the board to form the cell structure. As the foam progressed out of the plates, it encountered another much larger, not adjustable flat plate, followed by a 6-foot long piece of metal conveyor rollers that prevented the foam from looping at that point. The rollers rolled on top of the foam, and in an emergency like a foam loop between the plates and this section, could be lifted in ½ second by tripping an air valve. This would allow us immediate access to the area to clear the mess. The SuperTechs had to measure the board numerous times in a shift right at that point, between the flat plate and the upper conveyor. A few times I got the measuring tape stuck and it went under the conveyor for it’s full length of 6 feet getting crushed into the hot foam. The emergency trip to lift the conveyor could have been used, but this could have caused a "loop" and it wasn’t worth the hassle. Now if that would have been my arm under there, that would have been a different story!

Loop de Loop

At this point it was one long board of Styrofoam. The foam was pulled into the sawline by 4 air-craft tires riding on the top of the board. These were adjustable as well, so we could apply different pressure for different boards. The speed of the draw, that is, of the motor pulling the foam, was adjustable at the die end by the SuperTech. By pulling it faster, we stretched the board, making it slightly thinner and narrower. By slowing it down, the board got wider. This is how we roughly controlled the width of the board. I say "roughly" because the sawline would do the final trim to exactly the right size. If we slowed the draw-rollers down too much, the foam would bunch up near the flat plates and the board would loop. It wasn’t unusual for the board to loop 30 feet into the air before someone noticed it, or it fell over sideways onto the floor like Charlie Chaplin in those silent movies.

Occasionally, if the pull by the tires was steady enough I would jump up on the conveyor and sit on the warm board for a ride to the other end. Only a few times did this cause a loop and to much disdain and disgust from my operators who had to handle the loop.

When a loop occurred, whoever noticed it first would sound an alarm, and a bunch of doors would suddenly open, like some game show or slapstick comedy, and a forklift would come racing in from the warehouse. All these guys running with a sharp knife in their hand like they are going to attack Frankenstein, converging before and after the loop to cut out the non-flat part. Quite humorous at times. When this was done, the piece still coming out of the die was guided back into the rollers. The long cut out piece was cut into manageable chunks of say 20 feet long, and dragged to the Styrofoam shredder for recycle. I had upsets that were so bad that we couldn’t clean the floor off fast enough and had to shut down the plant to do so! We’re talking about 3000 or 4000 square feet of concrete floor totally obliterated with bent, twisted, off-spec Styrofoam. Even if it was on-spec, we would recycle it; there was no provision for running it through the saw-line, nor was it worth the effort. If the foam was straight enough we could chop it up and put it on pallets, store it in the warehouse, then retrieve it when we needed more reclaim.

We had a number of alarms, five I think, for different areas, so that by sound alone we could determine where the problem was. Each would be triggered automatically by jam-ups or time-outs, and they could also be manually triggered. One such alarm was the one by the control room that I would use to signal operators for various tasks. It was quite noisy in the plant so phones were not that effective on the plant floor. I would give one big blast to signal a loop or jam-up. Two short blasts meant attention, e.g. start-up is imminent, or I need a sample. My job was to keep the Styrofoam on spec, and if it ever went off spec, or if I had changed a particular feed rate, analysis was necessary about every 15 minutes. Once I gave the attention signal the operator would look my way and I would then resort to hand signals. We became quite good at communication this way. We had hand signals for "check density", "check cell size", "there’s a piece of crap in the board that has to be carved out". For the last example I think I pointed at the board, then pretended to throw up. I had other signals for "board too wide" or "board too narrow". A board that was too wide would jam up at the entrance to the sawline, causing a loop, so the operator had to trim the edge with his knife before that happened. Too narrow a board meant the board would miss the cutters and therefore was scrap. Better to see it now and take the boards off now, than after they were strapped and palletized.

Sunday, November 08, 2020

AAhh. Looping. I remember it well. This was an effect where the soft board would suddenly have tension removed at one end, causing it to loop up in the air. Sometimes putting the upper conveyor down, or raising it would cause this to happen. Changing the angle of the flat plates near the die could have the same effect. Hell, more than once, just spreading an arm across the moving board so I could measure it’s width would cause a loop. This board traveled down a conveyor about 100 feet to the sawline.At this point it was one long board of Styrofoam. The foam was pulled into the sawline by 4 air-craft tires riding on the top of the board. These were adjustable as well, so we could apply different pressure for different boards. The speed of the draw, that is, of the motor pulling the foam, was adjustable at the die end by the SuperTech. By pulling it faster, we stretched the board, making it slightly thinner and narrower. By slowing it down, the board got wider. This is how we roughly controlled the width of the board. I say "roughly" because the sawline would do the final trim to exactly the right size. If we slowed the draw-rollers down too much, the foam would bunch up near the flat plates and the board would loop. It wasn’t unusual for the board to loop 30 feet into the air before someone noticed it, or it fell over sideways onto the floor like Charlie Chaplin in those silent movies.

Occasionally, if the pull by the tires was steady enough I would jump up on the conveyor and sit on the warm board for a ride to the other end. Only a few times did this cause a loop and to much disdain and disgust from my operators who had to handle the loop.

When a loop occurred, whoever noticed it first would sound an alarm, and a bunch of doors would suddenly open, like some game show or slapstick comedy, and a forklift would come racing in from the warehouse. All these guys running with a sharp knife in their hand like they are going to attack Frankenstein, converging before and after the loop to cut out the non-flat part. Quite humorous at times. When this was done, the piece still coming out of the die was guided back into the rollers. The long cut out piece was cut into manageable chunks of say 20 feet long, and dragged to the Styrofoam shredder for recycle. I had upsets that were so bad that we couldn’t clean the floor off fast enough and had to shut down the plant to do so! We’re talking about 3000 or 4000 square feet of concrete floor totally obliterated with bent, twisted, off-spec Styrofoam. Even if it was on-spec, we would recycle it; there was no provision for running it through the saw-line, nor was it worth the effort. If the foam was straight enough we could chop it up and put it on pallets, store it in the warehouse, then retrieve it when we needed more reclaim.

We had a number of alarms, five I think, for different areas, so that by sound alone we could determine where the problem was. Each would be triggered automatically by jam-ups or time-outs, and they could also be manually triggered. One such alarm was the one by the control room that I would use to signal operators for various tasks. It was quite noisy in the plant so phones were not that effective on the plant floor. I would give one big blast to signal a loop or jam-up. Two short blasts meant attention, e.g. start-up is imminent, or I need a sample. My job was to keep the Styrofoam on spec, and if it ever went off spec, or if I had changed a particular feed rate, analysis was necessary about every 15 minutes. Once I gave the attention signal the operator would look my way and I would then resort to hand signals. We became quite good at communication this way. We had hand signals for "check density", "check cell size", "there’s a piece of crap in the board that has to be carved out". For the last example I think I pointed at the board, then pretended to throw up. I had other signals for "board too wide" or "board too narrow". A board that was too wide would jam up at the entrance to the sawline, causing a loop, so the operator had to trim the edge with his knife before that happened. Too narrow a board meant the board would miss the cutters and therefore was scrap. Better to see it now and take the boards off now, than after they were strapped and palletized.

Shreddies

The shredder was a monstrous machine, the equivalent of a Great White Shark or Grizzly in the mechanical world. The unit was a solid steel drum with large, very sharp claws mounted on it called appropriately enough, "bear claws". As the drum rotated rapidly from the force of a 100 horsepower electric motor, the claws would dig into the foam and force it through a tough metal screen. Small pellets about ½" in diameter would fall out of the screen and get sucked up by a cyclone into the recycle bin. This bin had a large paddle inside to keep the foam chips from settling or forming bridges that would hold the foam up.

The shredder was a machine that could chew up a human body as well as it did the foam. Because of that, many safeguards were in place to prevent such a situation. As a standard there were emergency stop buttons on the outside of the conveyor feeding the shredder. The shredder itself, because it generated so much noise during operation, was set inside a sound-proof room, with thick plastic flaps allowing the boards to enter from the conveyor. To get into the room required a key, and once this key was turned, it would shut off AC power and turn on the DC brakes for the shredder motor. This would stop the motor quickly. A time-out feature would then be employed to make sure the brakes had enough time to stop the motor, after which the door was able to be opened. When the cover was opened to the bear claw drum, another switch was activated that removed power once again, so that even if a person were locked in the enclosure, with the cover up, the machine would not start.

Have you ever taken your kids to McDonalds and let them play in the caged area with all those colored balls? At Styro, we would have situations that were quite similar! One day the 10 foot by 10 foot room that the shredder was in became filled halfway up the walls with shredded foam when the cyclone became plugged. We had a hose inside the enclosure, so once the cyclone was running again, we could just suck up the room contents like we were using a big vacuum cleaner.

Sunday, November 08, 2020

The foam that went to the shredder had to be clean. If there was any wood from a pallet stuck in a piece of foam, it ended up in the reclaim. Then it went through the process and could get stuck in the die. Same could be said of dirt and rocks. So we had to keep the floors fairly clean. Night shift typically swept and washed the floors, broken pallets were set aside, not to be used until repaired.The shredder was a monstrous machine, the equivalent of a Great White Shark or Grizzly in the mechanical world. The unit was a solid steel drum with large, very sharp claws mounted on it called appropriately enough, "bear claws". As the drum rotated rapidly from the force of a 100 horsepower electric motor, the claws would dig into the foam and force it through a tough metal screen. Small pellets about ½" in diameter would fall out of the screen and get sucked up by a cyclone into the recycle bin. This bin had a large paddle inside to keep the foam chips from settling or forming bridges that would hold the foam up.

The shredder was a machine that could chew up a human body as well as it did the foam. Because of that, many safeguards were in place to prevent such a situation. As a standard there were emergency stop buttons on the outside of the conveyor feeding the shredder. The shredder itself, because it generated so much noise during operation, was set inside a sound-proof room, with thick plastic flaps allowing the boards to enter from the conveyor. To get into the room required a key, and once this key was turned, it would shut off AC power and turn on the DC brakes for the shredder motor. This would stop the motor quickly. A time-out feature would then be employed to make sure the brakes had enough time to stop the motor, after which the door was able to be opened. When the cover was opened to the bear claw drum, another switch was activated that removed power once again, so that even if a person were locked in the enclosure, with the cover up, the machine would not start.

Have you ever taken your kids to McDonalds and let them play in the caged area with all those colored balls? At Styro, we would have situations that were quite similar! One day the 10 foot by 10 foot room that the shredder was in became filled halfway up the walls with shredded foam when the cyclone became plugged. We had a hose inside the enclosure, so once the cyclone was running again, we could just suck up the room contents like we were using a big vacuum cleaner.

Don't Step on the Cow Patties

If dirt got caught in the die, and since this was recycled foam this was always a certainty, one or more strings would fall out and make little patties. If left too long, or if the entire strand collapsed because of strings falling and pulling on them, then it could make a BIG pattie. I saw some that were the size of a desk, and about 6" thick, so big that we almost couldn’t extract it from under the extruder because it flowed around the legs of the water bath, like some kind of lava. These would take many days to cool. Patties were allowed to cool for several hours so that they would harden into dense, brittle plastic. If they were big patties, they would be broken up into manageable chunks with a sledge hammer, then stored in barrels. Small ones were simply thrown in. These were then taken over to the pattie grinder where they were ground up into chips about the same size as the chocolate ones in Mr. Christie cookies. This reclaim was sucked up by the same cyclone as the pelletizer output. The pattie grinder shared the room with the Styrofoam shredder. We didn’t waste anything. This was such a neat process, almost nothing went to landfill, except for broken pallets or pieces of them.

Sunday, November 08, 2020

From the recycle bin, the foam dropped into the top of the reclaim extruder. Here the foam was compressed, heated and melted and allowed to exit the die as a strand of 8 separate strings of melted plastic. Allowed to fall on the floor just under the die would create a hot plastic pile called a "pattie" because of it’s similarity to cow patties out in the field! However this wasn’t normal operating practice; the strand was normally strung through an eight foot water bath where it was cooled and made very brittle. The end of the strand was then fed into the pelletizer which ground the strand up into small pellets like the styrene pellets. Just before it entered this grinder, a hot, very strong blast of air would strip the water off the strand so that the pellets would be dry, and transportable. Once again, a cyclone sucked up the pellets and dropped them off in the reclaim silo. By adjusting the extruder and bath temperatures, one could get just the perfect strand that was soft at the beginning and just brittle enough at the other end to get ground properly.If dirt got caught in the die, and since this was recycled foam this was always a certainty, one or more strings would fall out and make little patties. If left too long, or if the entire strand collapsed because of strings falling and pulling on them, then it could make a BIG pattie. I saw some that were the size of a desk, and about 6" thick, so big that we almost couldn’t extract it from under the extruder because it flowed around the legs of the water bath, like some kind of lava. These would take many days to cool. Patties were allowed to cool for several hours so that they would harden into dense, brittle plastic. If they were big patties, they would be broken up into manageable chunks with a sledge hammer, then stored in barrels. Small ones were simply thrown in. These were then taken over to the pattie grinder where they were ground up into chips about the same size as the chocolate ones in Mr. Christie cookies. This reclaim was sucked up by the same cyclone as the pelletizer output. The pattie grinder shared the room with the Styrofoam shredder. We didn’t waste anything. This was such a neat process, almost nothing went to landfill, except for broken pallets or pieces of them.

Playing the Strand

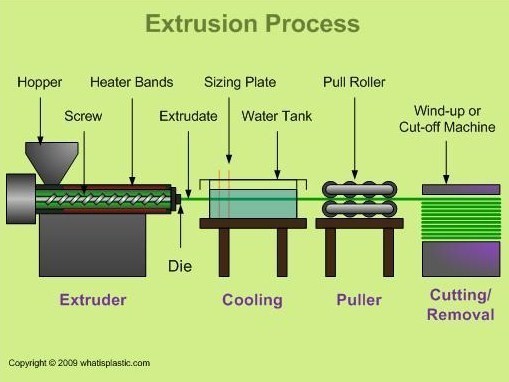

Since it was hot (200 deg C) and sticky, one could not use gloves, but had to use bare hands. The trick was to wet your hands first, grab the strand and plunge it underwater immediately, all the while pulling it gently and consistently through the trough. The trough had two barriers in it, like the barrier in a wall-paper water box, to keep the strand below the surface of the water, so stringing it out took a little bit of two-hand dexterity. A few times even a pro like myself had to do it more than once. If the bath temperature or extruder temperature were not right, the strand just would not flow, or it would be so brittle that as it tried to make the last bend just before entering the grinder, it would break right at that point. The graphic at right shows the process. Our extruder was vertical and rather than wind the strand, we chopped it up into little bits.

Sunday, November 08, 2020

Getting the hot strand going again took a little practice initially to develop a technique.Since it was hot (200 deg C) and sticky, one could not use gloves, but had to use bare hands. The trick was to wet your hands first, grab the strand and plunge it underwater immediately, all the while pulling it gently and consistently through the trough. The trough had two barriers in it, like the barrier in a wall-paper water box, to keep the strand below the surface of the water, so stringing it out took a little bit of two-hand dexterity. A few times even a pro like myself had to do it more than once. If the bath temperature or extruder temperature were not right, the strand just would not flow, or it would be so brittle that as it tried to make the last bend just before entering the grinder, it would break right at that point. The graphic at right shows the process. Our extruder was vertical and rather than wind the strand, we chopped it up into little bits.

Now That your Mine, I Saw the Line

Sunday, November 08, 2020

The sawline took the long continuous board that was coming out of the die and chopped it up into 8 or 4 foot lengths, whose sides were then trimmed. We could do a straight flush cut so the Styrofoam, when installed, would simply be butted together or a "ship-lap" cut where the foam had an off-set edge on both sides that would overlap each other when installed. The saws used for the edges were large massive cylinders with many tiny teeth on the surface that cut the board smoothly without tearing. The cut-off saw that cut the boards to rough length was like a big bread knife: it was reciprocating and moved to and fro at the same speed that the foam line was moving so that it could cut the board without binding.

What a Cool Tower

Sunday, November 08, 2020

The boards then went to a cooling tower, a huge piece of machinery that accepted about 50 boards, one board at a time. It was built like a Ferris wheel, with each "car" taking one board. The Styrofoam at this point was still hot in the middle, making it difficult to trim properly, or even stack properly because the boards would stick together. The tower was designed to give the boards enough time to cool. If the board was real thin, this tower appeared to rotate almost continuous, but then the board was thin, not requiring much cooling. If the board was thick, say 3-1/2", the thickest we made, it would rotate much slower because it required lots of cooling. One night shift a large bearing that supported the bottom shaft of the tower broke and the whole tower stopped. It wasn’t possible to keep the plant running because all the boards would have had to be removed just after cutting to rough length, and we couldn’t stack them on a pallet without them sticking together. So I shut down the plant at about 3 AM and called out a millwright. It took him and the other millwright who came in at 8 AM all day to fix it. This was unfortunate because that meant I would start up the plant that evening. (I hated startups, not because of the work involved, but because it was tough not to make scrap for many hours, and I hated making scrap. The longer the plant was down, the better the chance that good board would not be made for hours.) There was a fairly long process lag, or latency, i.e. from the time a process change was made to the time it affected the output was about 10-15 minutes, depending on production rate.

My Grade 7 Teacher was a Strapper Too

Friday, November 27, 2020

After the pile was cut, it dropped down to a waiting conveyor that could be operated continuously or single step. The pile changed direction and was sent to the strapper that put tough plastic straps on the ends of the bundles. We only called the grouping a "bundle" after it was tied together, before that it was just loose pieces of Styrofoam. This strapper was always breaking down. It was a complicated piece of machinery that basically had to wrap a strap completely around the foam pieces, then cut-off and seal the ends of the strap. The biggest problem was plastic dust or small pieces of strapping that would jam up the mechanism that did the cutting and sealing. The conveyor that was just before this machine could be put on single-step to allow us some latency so we could fix the strapper. If we couldn’t and the outlet conveyor filled up, then operators would have to take the loose pieces off and stack them on a pallet for strapping later on. This was a pain. After a number of years operating like this, the plant purchased another strapper, and put both of them on wheels so we could just do a swap, and work on the broken one at a later time. The problems weren’t always easy to fix, requiring the services of a millwright, but this method allowed us to keep running and not have to call out a millwright in the middle of the night.

Palltetizer

The palletizer which we obtained for the new plant was a huge piece of equipment, operated by a PLC (programmable logic controller), that interfaced to a hydraulic system. When an 8 foot bundle, or pair of 4 foot bundles entered the palletizer, they were elevated to the top of the palletizer where large forks pushed them from the conveyor to a flat, metal bed the size of a pallet. The fork would return to repeat this event for the next bundle. When the table was full, three 8-foot-bundles-worth, the table would drop by the height of a bundle, ready for another stack. When the table was full, it moved laterally over the stack of empty pallets where the load was deposited by a gate coming down to stop the foam as the table returned to it’s position. The loaded pallet was supported by large hydraulically operated forks that entered on both sides, and these in turn were connected to large cylinders that moved the entire system up and down. When the pallet was fully loaded with foam the cylinders would drop to the bottom, allowing the pallet to sit on an angled roller conveyor. The forks would come out and the pallet would roll down the conveyor ready to be picked up by the operator sitting on the forklift, reading a book. Yes, the palletizer sure saved a lot of manual labor. Being interested in machinery, I used to watch all this automated equipment in amazement. It was so well designed.

Friday, November 27, 2020

After strapping, the bundles moved down a 20 foot piece of roller conveyor (that is, a non-powered conveyor) and were allowed into the palletizer. In the old plant we didn’t have a palletizer and operators had to take the bundles off the conveyor and manually place them on a pallet that was 8 feet long by 10 feet wide. He had to pile them 8 feet high, then used the forklift to take the pallet to the warehouse. When he returned, he had a conveyor full of bundles to be palletized. If he was real late, the bundles could be backed up through the strapper back to the outlet conveyor.The palletizer which we obtained for the new plant was a huge piece of equipment, operated by a PLC (programmable logic controller), that interfaced to a hydraulic system. When an 8 foot bundle, or pair of 4 foot bundles entered the palletizer, they were elevated to the top of the palletizer where large forks pushed them from the conveyor to a flat, metal bed the size of a pallet. The fork would return to repeat this event for the next bundle. When the table was full, three 8-foot-bundles-worth, the table would drop by the height of a bundle, ready for another stack. When the table was full, it moved laterally over the stack of empty pallets where the load was deposited by a gate coming down to stop the foam as the table returned to it’s position. The loaded pallet was supported by large hydraulically operated forks that entered on both sides, and these in turn were connected to large cylinders that moved the entire system up and down. When the pallet was fully loaded with foam the cylinders would drop to the bottom, allowing the pallet to sit on an angled roller conveyor. The forks would come out and the pallet would roll down the conveyor ready to be picked up by the operator sitting on the forklift, reading a book. Yes, the palletizer sure saved a lot of manual labor. Being interested in machinery, I used to watch all this automated equipment in amazement. It was so well designed.

Safety

Besides running the saw-line on manual using all the photocells the interlocks and PLC control, we could switch any section for full manual control. For example, every step of the complex palletizer was capable of being accomplished by pressing individual buttons. On the palletizer, this was quite necessary to have because of the pallets we used. They weren’t always the same thickness of boards. They weren’t always in good shape, with pieces broken off and hanging by a bent nail. The photocells sometimes went out of alignment. All these things usually meant some kind of jam-up, making it necessary for us to clear the jam by "jogging" the various systems. After fixing the problem we would switch it over to automatic, ready to switch back to manual if we saw an impending problem. If it worked on auto for a couple passes, we knew it would be okay.

em ipsum dolor sit amet, consectetur adipisicing elit, sed do eiusmod tempor incididunt ut labore et dolore magna aliqua.

Friday, November 27, 2020

All of the equipment was interlocked with others so that jam-ups could not occur. Many photocells determined the position of the board or bundle at all times, shutting off conveyors or motors until any back-log was cleared. However there was a limit to how long we could spend in any one area before we had to resort to manual control, like stacking boards by hand. But the conveyors were long enough that it gave us some capacity for fixing minor problems without having to do that. If a problem was serious enough (like the cooling tower was ) we would have to shut down.orBesides running the saw-line on manual using all the photocells the interlocks and PLC control, we could switch any section for full manual control. For example, every step of the complex palletizer was capable of being accomplished by pressing individual buttons. On the palletizer, this was quite necessary to have because of the pallets we used. They weren’t always the same thickness of boards. They weren’t always in good shape, with pieces broken off and hanging by a bent nail. The photocells sometimes went out of alignment. All these things usually meant some kind of jam-up, making it necessary for us to clear the jam by "jogging" the various systems. After fixing the problem we would switch it over to automatic, ready to switch back to manual if we saw an impending problem. If it worked on auto for a couple passes, we knew it would be okay.

em ipsum dolor sit amet, consectetur adipisicing elit, sed do eiusmod tempor incididunt ut labore et dolore magna aliqua.

Testing and Quality Control

We had a thickness monitor there as well. Of all the specs we had to watch, density was the most important, so in the old plant that did not have a densitometer, we would do an analysis minimum every hour. During startup, an upset, or a production rate change, we could do these continuously, until we reached spec. With the densitometer, we could read the value continuously, but still, for a record, do the analysis every hour. This was an easy test: cut a block of Styrofoam from a board off the line, measure the exact dimensions, then weigh it on a very sensitive scale. Doing some simple math gave us the density in pounds per cubic foot. I think our spec was 1.5 lb./cu.ft. There was nothing wrong with the value higher than that (denser), but it meant we were giving extra product away. If it was less, then the compression strength wouldn't be there, so we tried to keep it over 1.5. A sample of 1.45 was just passable if we made immediate corrections, i.e. we were not allowed to make a bunch at that value. All pallets that went into the warehouse had information on it that included the density value.

Another test that we performed "once in awhile" was the R-value test. We would cut a 4" square piece of foam and put it in an oven with a temperature sensor on one side. Measuring how fast the heat moved from one side to the next was a indication of R-value, or the insulation value of the foam. Styrofoam was superior to all other insulations in this regard; it had an R-value of 5 per inch. Nothing else comes close. Well, maybe the insulating tiles on the Space Shuttle would, but who wants to pay $1000 per tile? Besides, they'd probably fall off your roof.

We did a compression test, once in awhile. (I think the "once-in-awhiles" were really every day-shift, that is once a day, day-shift only). Here we subjected a piece of foam to a manual press and measured the deflection using a dial indicator.

Another very important test was for cell size. This test was fraught with error and required much skill to perform. A small block of foam was cut out of a board and a section was shaved off using a commercial meat-slicer. The thinner we made the slice, the more accurate the cell count would be, but trying to get it thin with the WRONG piece of equipment was very difficult. I say "wrong" because I know that medical labs can slice human tissue by cell thickness using the right equipment, e.g. a microtome. (In fact, having just undergone a laser eye operation, I know the equipment exists to slice small sections of the cornea, as was done to me). After we sliced the sample in this crude fashion we put it under a microscope and counted the number of cells to determine cell size. I think the units in tenths of a millimeter as in "the cell size is .31 mm." (C'mon man, it's been 20 years, I can't remember everything!)

Friday, November 27, 2020

We had a small, non-chemical lab where we did product testing. In the new plant we had a radio-active densitometer that measured the density of the board as the board passed above it on the long cooling conveyor. When the board wasn't passing over the densitometer, a little shutter was triggered that covered the radioactive source to keep it away from personnel. Well, ever the experimenter and VERY curious of WHY we needed the shutter, I defeated the trigger mechanism to keep the shutter open. Then I looked inside. Nothing to see. No green rays or anything. I think I was hoping the radiation would give me super powers like The Green Hornet, or Spiderman. (My last eye examination pointed out the need for -8.5 diopter correction, which means lenses the size of Coke bottle bases.)We had a thickness monitor there as well. Of all the specs we had to watch, density was the most important, so in the old plant that did not have a densitometer, we would do an analysis minimum every hour. During startup, an upset, or a production rate change, we could do these continuously, until we reached spec. With the densitometer, we could read the value continuously, but still, for a record, do the analysis every hour. This was an easy test: cut a block of Styrofoam from a board off the line, measure the exact dimensions, then weigh it on a very sensitive scale. Doing some simple math gave us the density in pounds per cubic foot. I think our spec was 1.5 lb./cu.ft. There was nothing wrong with the value higher than that (denser), but it meant we were giving extra product away. If it was less, then the compression strength wouldn't be there, so we tried to keep it over 1.5. A sample of 1.45 was just passable if we made immediate corrections, i.e. we were not allowed to make a bunch at that value. All pallets that went into the warehouse had information on it that included the density value.

Another test that we performed "once in awhile" was the R-value test. We would cut a 4" square piece of foam and put it in an oven with a temperature sensor on one side. Measuring how fast the heat moved from one side to the next was a indication of R-value, or the insulation value of the foam. Styrofoam was superior to all other insulations in this regard; it had an R-value of 5 per inch. Nothing else comes close. Well, maybe the insulating tiles on the Space Shuttle would, but who wants to pay $1000 per tile? Besides, they'd probably fall off your roof.

We did a compression test, once in awhile. (I think the "once-in-awhiles" were really every day-shift, that is once a day, day-shift only). Here we subjected a piece of foam to a manual press and measured the deflection using a dial indicator.

Another very important test was for cell size. This test was fraught with error and required much skill to perform. A small block of foam was cut out of a board and a section was shaved off using a commercial meat-slicer. The thinner we made the slice, the more accurate the cell count would be, but trying to get it thin with the WRONG piece of equipment was very difficult. I say "wrong" because I know that medical labs can slice human tissue by cell thickness using the right equipment, e.g. a microtome. (In fact, having just undergone a laser eye operation, I know the equipment exists to slice small sections of the cornea, as was done to me). After we sliced the sample in this crude fashion we put it under a microscope and counted the number of cells to determine cell size. I think the units in tenths of a millimeter as in "the cell size is .31 mm." (C'mon man, it's been 20 years, I can't remember everything!)

Big Bertha

Friday, November 27, 2020

The startup of the both plants (the small portable and then the larger fixed plant) each produced a big ball of crud that we named Big Bertha, and I do believe Reg took both of them home for souvenirs. (He lived on an acreage). Because all the piping was new and could contain all kinds of foreign material like grease, oil, pieces of metal, or Jimmy Hoffa, we purged the system with polyethylene plastic first followed by styrene. I think there may have been some kind of lubricant mixed in with the whole she-bang. Like giving castor oil to your cat with the hairball. In any case, when this gross conflagration exited through the wide open die, operators stood by and stuck all the stuff together forming it into a big ball like they were making bread dough. This ball was about 4 or 5 feet in diameter. Reggie probably uses the Berthas for a tourist attraction. Phone him up and see.

Ear Muffs in Summer?

All the saws were enclosed in sound-proof enclosures, not for the safety considerations (although they did provide this function), but in order to cut down the noise. These were metal boxes with the inside panels full of little holes, the outside very solid. In between the 4 inch walls was Fiberglass insulation. Yes, competitor product. Of course the board had to enter and exit these enclosures, and despite the heavy plastic sheeting acting as "doors", there was still sufficient noise to warrant wearing hearing protection. All the operators, including myself had head phones attached to our hard hats.

Friday, November 27, 2020

It was noisy in the plant, with all the fans, cyclones and saws running. In the old plant there wasn’t as much noise control because the plant was meant to be portable. In fact, the "control room" wasn’t even a room. The SuperTech desk sat by the extruder and related control panel equipment and it was right out in the open. When I sat there to eat my lunch during an upset or a startup, I did so with hearing protection (ear muffs) on. I’d return to my lunch to find it dusty with some kind of dust. No wonder I’m sick! In the new plant we had a control room that was sound proof. Much better.All the saws were enclosed in sound-proof enclosures, not for the safety considerations (although they did provide this function), but in order to cut down the noise. These were metal boxes with the inside panels full of little holes, the outside very solid. In between the 4 inch walls was Fiberglass insulation. Yes, competitor product. Of course the board had to enter and exit these enclosures, and despite the heavy plastic sheeting acting as "doors", there was still sufficient noise to warrant wearing hearing protection. All the operators, including myself had head phones attached to our hard hats.

Collecting

I also used the rolls to make a light sculpture. I mounted different-length cylinders on a ½ sheet of plywood, then hung it upside down from the ceiling. I then put different color lights in each column which I could control by switches or computer, turning on different colors at any one time. It was really neat and looked quite nice. I left it there when I moved.

Friday, November 27, 2020

People that know me know I’m a collector. I think I started collecting things with this job. First of all there were the empty spool center-sections from the strapping material. These were cylindrical, about 6 inches long, 5 inches outside diameter and 4 inches inside diameter. They were made of very dense, compressed cardboard material and were as strong and heavy as an equivalent wood piece would be. We generated 1 or 2 of these things every day and they were just thrown in the garbage. Seeing that I could get a "lot" of these things over the years, I decided to collect them for some use later on, like maybe a Great Wall of Founda. I had no idea what to do with them until I had a whole bunch. The other shifts collected them for me as well, so I was bringing home maybe 10 a week so that I had hundreds of them by the time I quit. By then I was at my new home on an acreage that had an unfinished basement, so I decided to use them there, to make a wall by glueing the spools together end to end into a column about 8 feet long. I then glued the columns together and stained the light-brown cardboard surface with a dark walnut stain. The wall was about 6 feet wide, so I used quite a few rolls there. Looked like hell when I was finished, but I put too much work into it to take it down. It was unique, so hopefully that factor off-set the awful looks of it.I also used the rolls to make a light sculpture. I mounted different-length cylinders on a ½ sheet of plywood, then hung it upside down from the ceiling. I then put different color lights in each column which I could control by switches or computer, turning on different colors at any one time. It was really neat and looked quite nice. I left it there when I moved.

Big Boxes

Friday, November 27, 2020

Occasionally we received styrene and reclaim in huge 1000 pound boxes that we would place on the production floor near the control room and use a suction wand to suck it up into the feed hoppers. The boxes were usually thrown out or used to store junk. I brought ½ dozen of these home and carved holes into them to make a large interconnecting "village" for my kids. Each box could hold a standard size kitchen table, so the boxes were quite large, so that the village took up lots of space in the rumpus room. I recently saw a Larson cartoon where two Army scientists are arguing over who should get the box from the latest ICBM missile shipment for their kids. Obviously my idea was not unique.

This is Art